With expected increases in global cotton production, prices aren’t likely to increase. Nonetheless, seed companies invest in varieties with improved water-use efficiency, enhanced disease resistance and increased flexibility for in-season management.

As a fiber, feed and food crop, cotton is unrivaled around the world as an agricultural crop that, as the U.S. National Cotton Council notes, provides thousands of useful products and supports millions of jobs as it moves from field to fabric. And as the world’s population rockets toward 8 billion (it reached 7 billion in 2012), the need and demand for cotton will continue to climb.

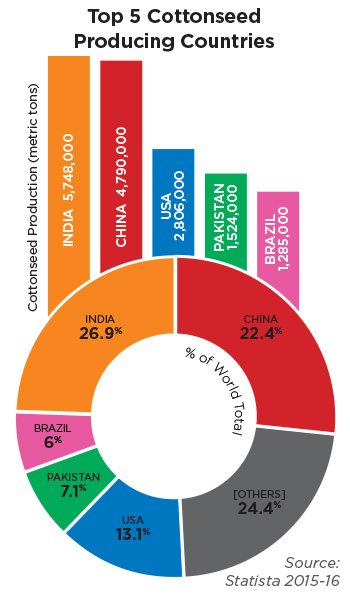

Around the world, 73.3 million acres were devoted to the production of the 2015-16 crop, which produced more than 106 million bales, according to the U.S. Department of Agriculture (USDA). The Top 5 cotton-producing countries include India, China, United States, Pakistan and Brazil. China traditionally sat atop the heap but was surpassed by India last year as China introduced policies to trim production and reduce government stockpiles.

The USDA predicted that 2016-17 world cotton production would increase 4 percent from the previous year to about 110 million bales, with the bulk of increases coming from India and the United States. While production is expected to increase, mill use consumption lags, which has increased ending stocks and forced prices lower. This slashes hope for near-future production increases.

U.S. Cottonseed Production

Upland cotton intentions are 10.8 million acres, up 8.8 percent from 2016, while extra-long staple (ELS) intentions of 266,000 acres represent a 36.9 percent increase.

“Planted acreage is just one of the factors that will determine supplies of cotton and cottonseed. Ultimately, weather, insect pressures and agronomic conditions play a significant role in determining crop size,” says Jody Campiche, NCC vice president of economics and policy analysis.

She says that with abandonment assumed at 12 percent for the United States, the Cotton Belt’s total harvested area is 9.7 million acres. Using an average U.S. yield per harvested acre of 830 pounds generates a cotton crop of 16.8 million bales, with 16 million upland bales and 760,000 ELS bales.

“History has shown that U.S. farmers respond to relative prices when making planting decisions,” Campiche notes. “During the survey period, the cotton December futures contract averaged 70 cents per pound, which is higher than year-ago levels. Looking at competing crops, corn prices were lower than year-ago levels while soybean prices were about 12 percent higher. The price ratio of cotton to corn is more favorable than in 2016.”

Cottonseed Producers

The world’s leading producers of cottonseed represent a who’s who list of crop genetics leaders. While no definitive list of the world’s top cottonseed companies can be found, the leaders include in no particular order: DuPont Pioneer, Bayer, Monsanto, Americot Inc., Navdanya Seed Co. (a network of “seed keepers” in India), Biocentury Transgene, Zhongnongfa Seed, Gansu Dunhuang Seed, Grand Agriseeds, Hefei Fengle Seed, Henan Qiule, Longping High-tech, Winall Hi-tech Seed, Dabeinong Technology Group and Wanxiang Doneed Co.

In the U.S., major cottonseed producers and brands include Americot, Inc. (NextGen), Monsanto (Deltapine), Bayer (FiberMax, Stoneville), Dow AgroSciences (PhytoGen), Winfield (Croplan). Other common brands include Dyna-Gro and All-Tex.

The Deltapine brand of upland cottonseed was the most popular planted in the U.S. for the 2016-17 season, according to the USDA-Agricultural Marketing Service’s Cotton and Tobacco Program. The Americot brand was the second most popular followed by Bayer’s FiberMax, Dow’s PhytoGen and Bayer’s Stoneville. Transgenic varieties accounted for about 98.7 percent of the upland cotton planted in the United States in 2016.

Americot product manager Brad Littlefield reports that the company’s NextGen 3406 was a top-planted variety in the U.S. this year. He attributes the success of Americot’s NextGen 3406 seed to its adaptability to a wide variety of soil types, planting dates and more.

“The variety has performed well across the Cotton Belt from Arizona to the Carolinas,” he says.

Giving Growers What They Need

“Growers are looking for varieties that perform very well, in terms of yield, and have a premium or better-than-average quality,” says Americot’s Littlefield. “We see a trend in domestic demand for higher quality cotton.

“To help growers meet this demand, we try to bring them varieties that will deliver a high-yielding cotton with premium qualities without giving up storm-proofness (i.e.: the lint remains in the boll for a longer period). Like farmers everywhere, cotton growers are looking for good products at a good price that will provide a return on their investment in seed.”

Lee Rivenbark, Bayer vice president for North America, says trends in the cottonseed market include increasing water-use efficiency in varieties, increasing the availability of disease resistance native characteristics, and providing additional management flexibility for growers to manage pests, including weeks in-season.

“What this means for growers and the global community is we will use less pesticide to grow cotton,” Rivenbark says. “Since the introduction of Bt cotton, the industry has reduced pesticide use by 37 percent, including a 42 percent drop in insecticide use.”

Rivenbark says the greatest challenge for cottonseed companies is to provide growers with solutions for their agronomic needs.

“To do that, we must envision the characteristics and traits growers need in the next decade,” he says. “We also constantly work to improve existing traits.

“For instance, in 2017 we launched TwinLink Plus, which offers three-gene Bt protection from worms, reduces the likelihood that a grower will need to make an insecticide treatment in-season to control economically damaging caterpillar pests, and improves the long-term effectiveness of the trait by employing three genes. We already were working on TwinLink Plus when we introduced TwinLink in 2014, which is why we could move to varieties with the three-gene trait so quickly.”

Adapting to Reality

The reality for today’s broadacre growers is that what works in one corner of the Cotton Belt might not work in another corner, and what works for a soybean grower in Illinois may not work for his counterpart in Mississippi, explains Bayer’s Rivenbark.

Considering that, Bayer recently committed nearly $1 billion for new facilities in the United States. These expenditures are part of a Bayer global investment program that started in 2013. Total capital expenditures between 2013 and 2016 were approximately $3.3 billion.

One of the larger expenditures was an additional $16.7 million investment in research and breeding in Lubbock, Texas, to further expand the company’s extensive cotton operations, plus research, breeding and trait development for the essential West Texas region. Bayer also expanded its Southeast cotton research with a new facility in Dawson, Ga.

Another reality for the industry is that growing cotton is about more than how many pounds you can harvest on each acre.

“The quality of that lint must grade out at premium levels to meet milling demands and to increase each grower’s opportunity for profit,” Rivenbark says. “No other cottonseed company is doing what Bayer is to advance cotton from research and development all the way to downstream marketing programs, including quality-focused programs such as Certified FiberMax Cotton, Shields Authentic Stoneville Cotton, and e3 cotton, which also focuses on environmental stewardship, social equitability and economic sustainability.”

Looking Forward

How seed companies meet the future needs of cotton growers relies on seed research and seed and crop management being conducted today.

“Three essential areas going forward are water-use efficiency, in-season traits and early-season protection,” Rivenbark says. “It’s universally accepted that we need to be smarter about how we use water in every area of our lives.

“That also holds true in the cotton field. To help growers produce more cotton while using less water, FiberMax and Stoneville cottonseed varieties are bred for drought tolerance and water-use efficiency. To build on these native characteristics, we are researching a drought-tolerance trait.”

While also working on new varietal traits, Americot is working to respond to another need of the cotton industry: an additional, affordable option for weed control, as some popular herbicides will not work in all situations.

“The problem of weed resistance has taught the cotton industry that sometimes you have to go backward to move forward,” Littlefield says. “Cotton growers in the past couple of years have taken a step back and are once again concentrating of basic field preparation, such as using ‚Äòyellow‚Äô herbicides (trifluralins) early to get a good clean start.

Littlefield acknowledges the major chemical companies, such as Monsanto, Bayer and BASF, have done a good job of re-educating growers on how to start clean and stay clean by using residual chemistries and other field preparation techniques to preserve and extend the life of new seed technologies.

“We have to go back and do some of the things that once were done with conventional cotton to protect new technologies while keeping weed escapes to a minimum,” he says.

The Downstream Push

The continued popularity of cotton as a utilitarian fabric and a viable field crop in the United States is largely the result of check-off dollars put to work by organizations such as The Cotton Board, the NCC and Cotton, Inc.

Based in Memphis, Tenn., The Cotton Board is the oversight and administrative arm of the Cotton Research & Promotion Program, representing U.S. upland cotton. The Cotton Board is responsible for providing the program with strategic leadership and oversight of the economic resources devoted to the program.

To fund the program, The Cotton Board collects a per bale assessment on all upland cotton harvested and ginned in the United States, as well as an importer assessment on the cotton content of all upland cotton products imported into the United States. The Cotton Board contracts with Cotton Inc. to carry out the research and promotion activities for U.S. producers and importers of cotton.

While Cotton Inc. is consumer and trade focused, it is a charged function of The Cotton Board’s mission to keep U.S. producers and importers of cotton informed on the innovative developments stemming from the Cotton Research & Promotion Program.

Cotton Inc.’s world headquarters and research center is located in Cary, N.C., and its consumer marketing headquarters is located in New York, N.Y. Supporting offices are located around the globe in Mexico City, Osaka, Shanghai and Hong Kong.

These groups work night and day to ensure cotton continues to be “The Fabric of Our Lives.”