Elaborate professional crop cleaning by innovation.

Real losses begin after harvest. Post-harvest loss is estimated to be one third of the global grain production, corresponding to approximately 1.3 billion tons with a yearly value of USD$1 trillion. The best way to minimize loss is to use appropriate technologies, however, the juxtaposition of machines does not yet constitute a technology. Foremost the proper machine selection, its configuration, feeding and bypass functions as well as the state-of-the-art nature of the individual machines determine functionality, sorting quality and cost-effectiveness.

“That’s why at PETKUS engineering, technology and innovation go hand in hand,” emphasizes Mark Scholze, CEO PETKUS Technologie GmbH.

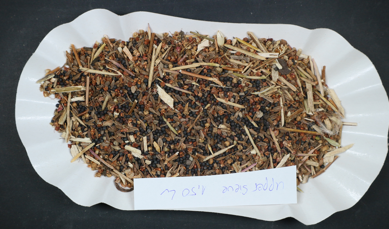

Mechanical, aerodynamic and optical sorting technologies are an essential contribution to hygiene management. In the PETKUS test centre, the samples rescued by optimal cleaning procedures pile up, which contain field-popped popcorn maize, red colored bran in white rice, sclerotinia in sunflowers, or ergot in rye. Bean weevils, ambrosia, cuscuta, deoxynivalenol or aflatoxin lead to post-harvest death if processing is inadequate. By contrast, investments in modern technologies are paying off.

A comparative analysis of the annual return on investment, where a conventional gravity table was compared with a PETKUS G 40mid-ex, showed that after the use of the Gmid-ex technology, sales per ton of sorted seeds were around 80 € higher than the previously installed technology. Using the same input lot with PETKUS Gmid-ex, the proportion of saleable seeds increased by 18 percent compared to the conventional table due to its increased sorting efficiency and precision. This represents a 12 percent increase in revenue per year.

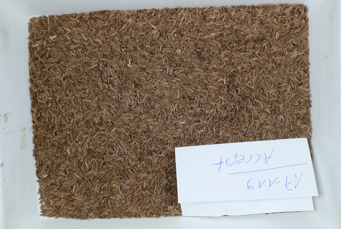

Furthermore, PETKUS evaluated an optimized sorting process for wheat contaminated with fusarium. Analysis of the raw material showed a DON content of 1.65 ppm.

“We were able to reduce the DON content to 0.82 ppm by means of optimized mechanical cleaning,” says Dr. Doreen Thoren, manager research department at ROEBER Institut GmbH. “Further processing by the ROEBER OS901 resulted in a final DON content of less than 0.25 ppm.”

In almost all plants, an air screen cleaner is the centrepiece. As a consequence, PETKUS positioned the air screen cleaner in the center of its innovations. PETKUS has launched the new M12s Cleaner that puts conventional flexibility, user-friendliness and efficiency to the test. Triple channel air classifiers, ultrasonic sensors, electrical sieve tensioning and a fold-out operating platform make seed clean and operator smile.

Air sifting is the bottleneck when the air screen cleaner runs at full capacity. The grain layer is too thick and cannot be sufficiently loosened. In addition, the air velocity of simple sifters is highest in the centre of the air flow. The separating process becomes inadequate.

“Those who do not have aerodynamic elements under control turn precision into a purely random principle,” says Dr. Khaled Raed, CIO ROEBER Institut GmbH.

The M12s Cleaner is therefore equipped with a completely redesigned sifting system. The triple channel sifter operates like a built-in gravity separator that loosens the grain layer before entering the three channels with different widths and correspondingly different air velocities. The height of the channels is electrically adjustable and adapted to the respective layer of material. The optimum height is controlled by ultrasonic sensors. Additional sensors continuously measure the air velocity and automatically control the air flaps. This guarantees a homogeneous air flow and enables its optimum setting.

As sieve changing is combined with some effort, the sieve changing procedure has been modified in the PETKUS M12s. The sieves are pushed into the sieve boxes on rollers and clamped all along the line by an electric U-bar.

“All these innovations have ensured that we have been able to reduce the time required for a screen change by 80%,” says Scholze. The M12s can be equipped with a touch panel for saving settings and for easy operation. The PETKUS M12s is regarded as the first smart screen cleaner and represents the technological leadership.