Ceradis addresses industry questions about the impact of biologicals in today’s rapid changing crop protection markets.

Biologicals are among the fastest-growing agricultural input categories with expectations for becoming one of several market disruptors responsible for reshaping the face of global crop protection.

As this technology continues to come to the forefront of the U.S. marketplace, Jan Stechmann, Vice President of Sales and Marketing for Ceradis Crop Protection, explains why his company is banking on biologicals as the next big wave of technology to take hold.

SW: What is driving the demand for biological products globally?

JS: The demand for biological-based solutions is growing due to several market conditions:

- Changes in regulatory policies due to consumer demand for less pesticide use. Around the world, regulatory agencies are banning active ingredients from continued use in agriculture. To meet new regulatory standards while maintaining food production demands, the industry is in a ‘step change’ to transition from all-synthetic inputs to integrated solutions that combine the use of conventional and biological products.

- R & D costs associated with new synthetic crop protection. The industry average for a company to bring a new synthetic crop protection product to market is around $300 million. In contrast, manufacturers of biological products can bring these types of tools to market for $10-$15 million.

- Biological inputs are proving to perform as well as synthetic market standards. Today, biological solutions are providing growers with both performance and economic benefit in comparison to market standards along with other benefits in handling, improved crop safety, and sustainability.

SW: What is Ceradis Crop Protection’s focus in regards to next-generation technologies including biologicals?

JS: Ceradis is focused on delivering differentiated science-based solutions with performance that stands out from the competition. Our portfolio is uniquely positioned to provide distinctive products either individually or through integrated use with synthetics crop protection and crop nutrition inputs.

SW: Does Ceradis currently offer a biological solution in the U.S.?

JS: In 2021 Ceradis introduced CeraMax, a biological seed treatment for the prevention of soilborne fungal diseases including Rhizoctonia and Fusarium virguliforme, the causal agent of Sudden Death Syndrome (SDS) in soybeans. With inherent performance and environmental advantages, CeraMax delivers multi-functional attributes that improve plant health, vigor, and yield, plus a level of safety that is not often offered with traditional synthetic-based seed treatments.

SW: How are growers embracing biologicals as an alternative to traditional seed treatments?

JS: Biologicals are demonstrating their value by addressing some of the biggest issues growers face right now, such as SDS in soybeans. The rapid adoption of CeraMax in geographies where SDS has a trending history represents an important validation of the market’s demand for biologicals in a row crop seed treatment offering.

Growers realize how biological inputs complement the plant’s genetics and traits, as well as traditional crop protection chemistry. By leveraging biologicals and conventional chemistry together, growers are well-equipped for becoming more productive, profitable, and sustainable.

SW: How are products like CeraMax providing greater confidence in grower adoption?

JS: Over the last 10 years, biological technologies along with their formulations, ease of application, and product-handling characteristics have significantly improved.

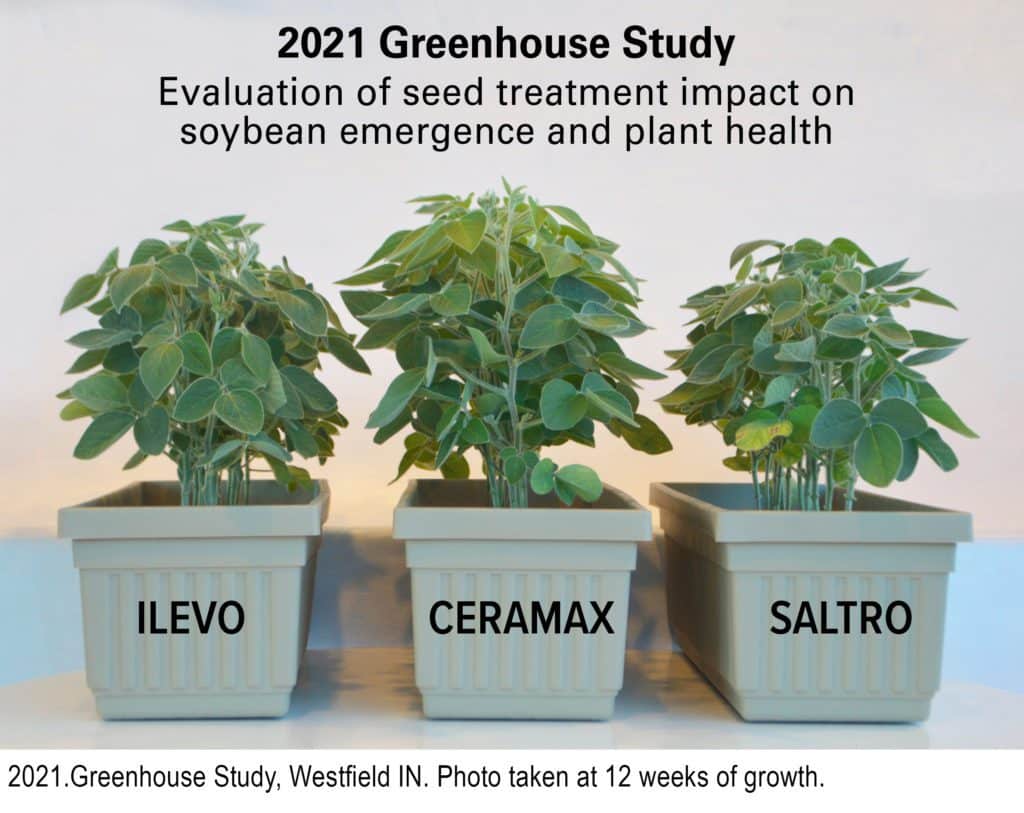

CeraMax, for example, is a model product for what the industry has been waiting for. It’s equivalent in SDS performance to synthetic seed treatments like Ilevo® and Saltro® but with better environmental stewardship features and greater economic value.

SW: What is behind CeraMax growing popularity in the U.S.?

JS: Soybean growers are gravitating to CeraMax because it’s the first SDS product of its kind with a new mode of action and a biological profile that is extremely safe for seed, plants, and microbial soil organisms.

CeraMax contains the active ingredient Natamycin, a biological molecule produced by soil bacteria that acts as a defense mechanism against soilborne diseases. Mitigating early-season risks, CeraMax delivers powerful protection plus a unique mode of action that helps battle resistance.

In comparison to synthetic seed treatments, CeraMax is an easy transition for growers wanting to move toward sustainable products without sacrificing performance.

SW: What are the benefits of using a biological seed treatment like CeraMax?

JS: Every year, approximately 20 to 40 percent of crop yields are lost due to pathogens, insects, and weeds. At the start of the season, CeraMax protects the seed by fighting off plant pathogens and minimizing biotic stress. CeraMax also helps growers reduce the use of synthetic crop protection inputs while ensuring strong root development, increased plant stands, plus plant vigor under varying environmental conditions.

SW: What kind of performance can growers expect from CeraMax?

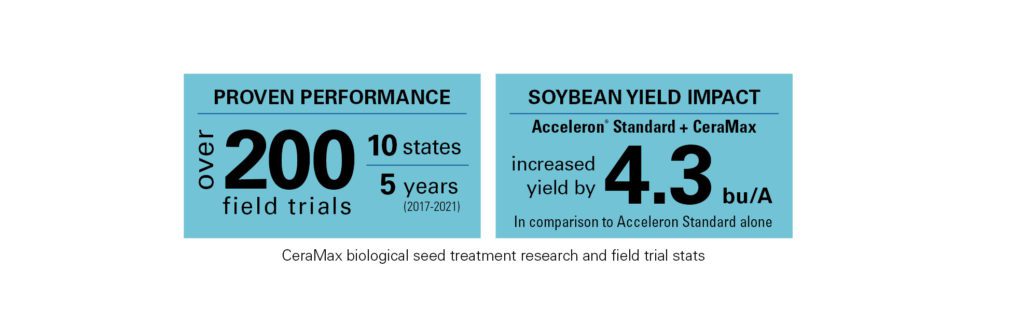

JS: CeraMax has proven its worth in the field. In multi-year research trials across 10 states, soybeans treated with the addition of CeraMax to Acceleron® Standard* showed significantly lower SDS disease incidence with an average yield increase of 4.3 bushels per acre compared to Acceleron Standard used alone. Based on 2021 commodity prices, growers who used CeraMax saw on average a $50 per acre increase.

CeraMax also delivers SDS protection without plant stress, including phytotoxicity, stunting, and reduced plant growth above and below ground.

SW: Does CeraMax provides advantages to the seed treatment blending process?

JS: CeraMax comes in a ready-to-use stable liquid formulation resulting in smooth blending for consistent seed coverage and adhesion. It also provides low use rate technology and is compatible across a broad range of seed treatments with excellent durability and a two-year shelf life.

SW: Where can growers buy CeraMax?

JS: CeraMax is commercially available through select distributors within the U.S. Channel partners who are currently selling CeraMax say the product is not only a good fit for their growers but also a unique offering that helps them differentiate from local retail competitors.

For growers, distributors, and retailers wanting to learn more about CeraMax, they can go to www.ceradis.com, or reach out by sending an email to jan.stechmann@ceradis.com.