Enter the Realm of Regulation

Time and cost savings help to drive investments in biological products.

The regulation of biological products is a bit of a mystery. If biologicals are in fact derived from the environment and are a naturally occurring product — just as worms and apples — then why would they need to be regulated?

Marrone Bio Innovations vice president of product management and businsess development, Jim Lappin, says that whether a biological product is regulated or not depends on what the product claims to do. For instance, if a product makes pesticidal claims, then it must receive regulatory approval from the U.S. Environmental Protection Agency. Located in Davis, California, Marrone Bio Innovations is a provider of biologically-based pest and plant health products for agriculture and other markets.

Even when there’s no genetic engineering, the regulatory challenges are still considerable and sometimes even insurmountable, says Gary Harman, Advanced Biological Marketing chief scientific officer, noting that is especially true in Europe. ABM is a developer, manufacturer and distributor of agricultural biologicals and employs about 40 people in Van Wert, Ohio. “In Europe, regulators have the philosophy of looking at products with a ‘what can go wrong’ eye,” he says.

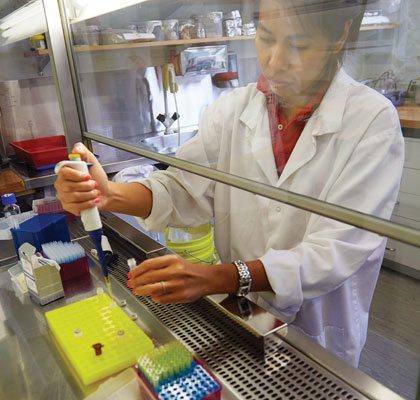

A BioConsortia researcher performs laboratory tests at its research and development facility in New Zealand.

In the United States, the registration process for biopesticides is governed by EPA’s Biopesticides Pollution Prevention Division.

EPA regulates three types of biopesticides — microbial pesticides, plant pesticides and biochemical pesticides. Microbial pesticides use a microorganism as the main ingredient. According to EPA, the most widely used microbial pesticides are subspecies and strains of Bacillus thuringiensis, or Bt. Each strain of this bacterium produces a different mix of proteins, and specifically kills one or a few related species of insect larvae.

Plant pesticides are substances produced by the plant from genetic material that has been added to the plant. For instance, researchers have taken the gene for the Bt pesticidal protein and introduced it into the plant’s own genetic material. Then the plant, instead of the Bt bacterium, manufactures the substance that destroys the pest. Both the protein and its genetic material are regulated by EPA; however, the plant itself is not regulated.

Under EPA’s rules, plant-incorporated protectants derived from genetic engineering are subject to the Federal Food, Drug and Cosmetic Act as well as the Federal Insecticide, Fungicide and Rodenticide Act. Whereas plant-incorporated protectants developed through conventional breeding are exempt from all FIFRA and FFDCA requirements, with the exception of the requirement that manufacturers report adverse effects.

Biochemical pesticides are naturally occurring substances that control pests by non-toxic mechanisms, such as insect sex pheromones that interfere with mating, as well as scented plant extracts that lure pests into traps. Because it is sometimes difficult to determine whether a substance meets the criteria for classification as a biochemical pesticide, EPA has established a special committee to make such decisions.

Recently the Biopesticides Pollution Prevention Division made a number of enhancements to provide additional guidance and help improve the efficiency of the regulatory process, reports the Biopesticide Industry Alliance. The alliance has posted guidance documents and data evaluation templates to its website to help expedite the registration process for its members.

Companies must be able to prove the efficacy of a product, which can also be a challenge. Harman says because of this, farmers in the EU are running out of options. ABM conducts business in Ukraine but is not currently in western Europe.

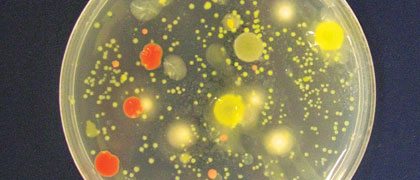

Colorful microbes form consortia or teams that work together to improve plant performance.

Cost Comparison

To register a synthetic chemical, Harman estimates that it costs about $100 million over a 10-year period. The timeline to bring a biological product from discovery to commercialization is radically different from that of a synthetic chemical. In total, it takes about six years to bring a new seed treatment to the market.

For example, in 2004, Dan Custis, CEO of ABM, said that the company needed to have its own Trichoderma strains. In 2006, researchers delivered the strains to ABM for testing. Then, from 2006 to 2008, the strains were field tested. In 2009, the company had its first year of significant sales. In this example, EPA was not involved, which allowed the product to be commercialized much faster than if it were.

ABM has 50 to 100 field trials per product to validate its research and products. “We have to make sure our products perform and perform consistently,” Harman says. Now, with its subsidiary in Africa, ABM can conduct field trials 365 days a year, moving even faster.

Another example is BioConsortia, which started funding a research and development breakthrough in 2011 with a process to rapidly identify teams of microbes that positively impact plant phenotypes and yield. BioConsortia already has multiple products in development.

Lappin from Marrone Bio estimates that it takes three to four years to bring a biological to market and $3 million to $6 million to launch in the U.S., compared to chemical products at $250 million and 10 years.

Manas Banerjee, president and CEO of Xite Bio, says biologicals offer a low-cost approach to enhancing yields. “Just in the research and development phase, it can cost anywhere from $1 million to $10 million for a biological,” he explains. “For an ag chemical, you’re looking more in the range of $70 million.”

Bob Streit, an independent consultant in Ames, Iowa, says when a new pesticide comes along and is biologically based, EPA will fast track it. “If the company with the new product asks for a label on three crops, EPA might grant a label for 20 crops,” Streit says. “That’s how much EPA and the U.S. Department of Agriculture are on board in getting these new strategies into crop production. That’s because these new products present little or no challenge to the environment and the soils.”

Streit says that part of the problem is that we don’t have enough scientists and university researchers working in this area, because these are not high profile projects.

The Pathway to Market

Examples are Trichoderma and Bacillus, which exist in nature. “If you look at the soil, you will find many different strains,” Harman says. “We isolate strains from field soils, on roots and natural substrates. Some come from compost, roots of plants or even the shell of a hickory nut. Once we have a collection, the strains go through a phenotypic screening process that looks at disease and insect control and plant growth promotion. Then, we screen based on genetics. Our strategy is to let lab screening determine which strains have desirable traits. None of our strains are the result of bioengineering.”

Harman says that his team takes advantage of what’s in nature. “We filter out inferior strains using genetic and genomic techniques, which leaves us with naturally occurring, genetically superior and better performing strains,” he says, noting that every strain is different.

Through a proprietary selection proc

ess, the ABM team segregates genetically superior strains and applies them to the seed as seed treatments. “The amount that we actually apply to the seed is 10,000 lower than what you find in the soil,” Harman says. “When the seed is planted, the fungi colonize the root and grow with the root, causing an increase in plant performance.”

Julie Deering