If there’s one thing I’ve learned after years of working on seed plants, it’s this: most projects don’t fail because of the wrong equipment. They fail long before that — at the planning stage.

Too often, processors start by calling an equipment supplier and asking for quotes on specific machines. That’s a natural instinct, but it’s backwards. The seed plant isn’t just a collection of parts — it’s a system. If you start with the shiny pieces, you miss the bigger picture: flow, space, budget, and, most importantly, the people who will run it.

The real inside story is that early conversations matter more than anything else. A rough sketch on a napkin can evolve into a great plant if the questions behind it are solid: What are your goals? Where do you see your capacity five years from now? How do you want your seed quality measured? Those conversations steer everything that follows.

- The Hidden Pitfall: Assuming Bigger Means Better. There’s huge pressure in today’s market for bigger plants with more throughput. And yes, the demand is real — there’s more seed to process every year, and less labour to do it. But here’s the part people don’t always see: scaling up can undermine seed quality if you don’t obsess over the details. Conveying equipment, spout lengths, discharge speeds — these aren’t glamorous topics, but they make the difference between seed that’s sale-ready and seed that’s been beaten up by its own plant.

- 3D Models Aren’t Just Eye Candy. Another inside edge: 3D modeling. It’s not a gimmick — it’s a safety net. On paper, a plant can look perfect, but when you spin it around in a model you start catching problems: spouts that are too close, maintenance walkways that don’t fit, equipment that won’t clear the ceiling. Every mistake you fix in the model is one you don’t have to fix on site — and that saves time, money, and headaches.

- The Coordination Trap. People ask me all the time how projects go “seamlessly.” The truth is, they don’t. There are always hiccups. The secret is experience — not just ours, but the network of engineers, electricians, contractors, and automation experts who’ve been through these jobs before. A project comes apart fast when you bring in people who don’t know seed plants. You end up paying for their learning curve.

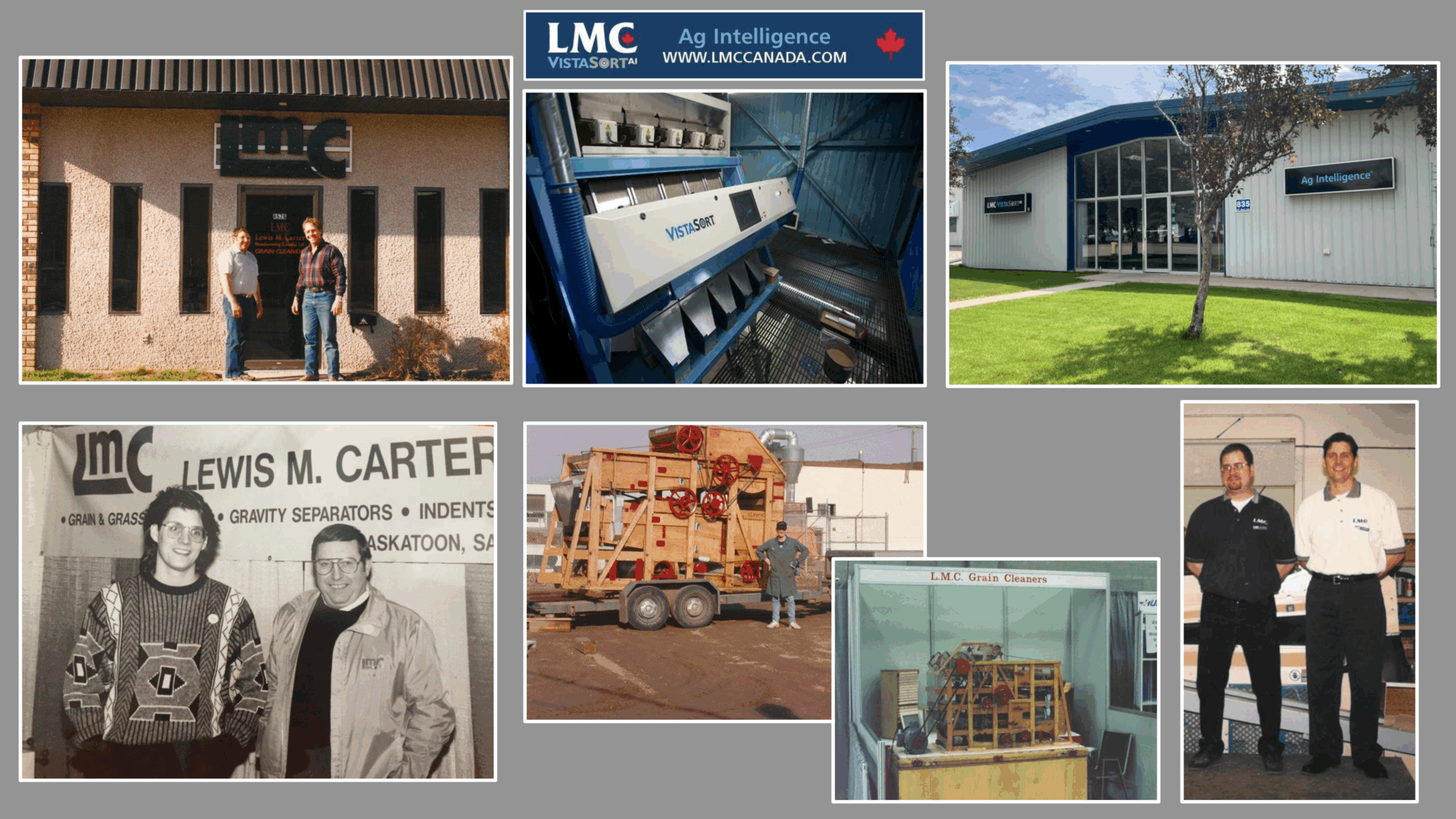

- Why Local Presence Still Matters. I know we live in a digital age, but here’s something you can’t Zoom: standing with a processor on their site, looking at a piece of equipment, and solving the problem in real time. That’s why Nexeed has built a team across the Prairies. It’s not just about being responsive — it’s about showing customers we’re not going anywhere. Stability and presence still count for a lot in this industry.

- The Best Education Isn’t in a Classroom. If you’re serious about a new build or an upgrade, you don’t necessarily have to start with me. Start with your neighbours. Visit plants. Ask what they regret and what they like. Ask what they’d never do again. That’s where the real learning happens, because seed cleaning isn’t theory — it’s practice.

The best decisions in this industry don’t come from textbooks — they come from the field. For me, that foundation traces back to my family’s farm in Treherne, Man. I didn’t choose to make that my life’s work, but the lessons I learned growing up there continue to shape how I approach every project today.

The next time you see a brand-new plant with gleaming equipment, remember: the real work happened months or even years before the first shovel hit the ground. The real inside story is that seed plants succeed — or fail — long before construction begins.

For more info visit nexeed.ca.