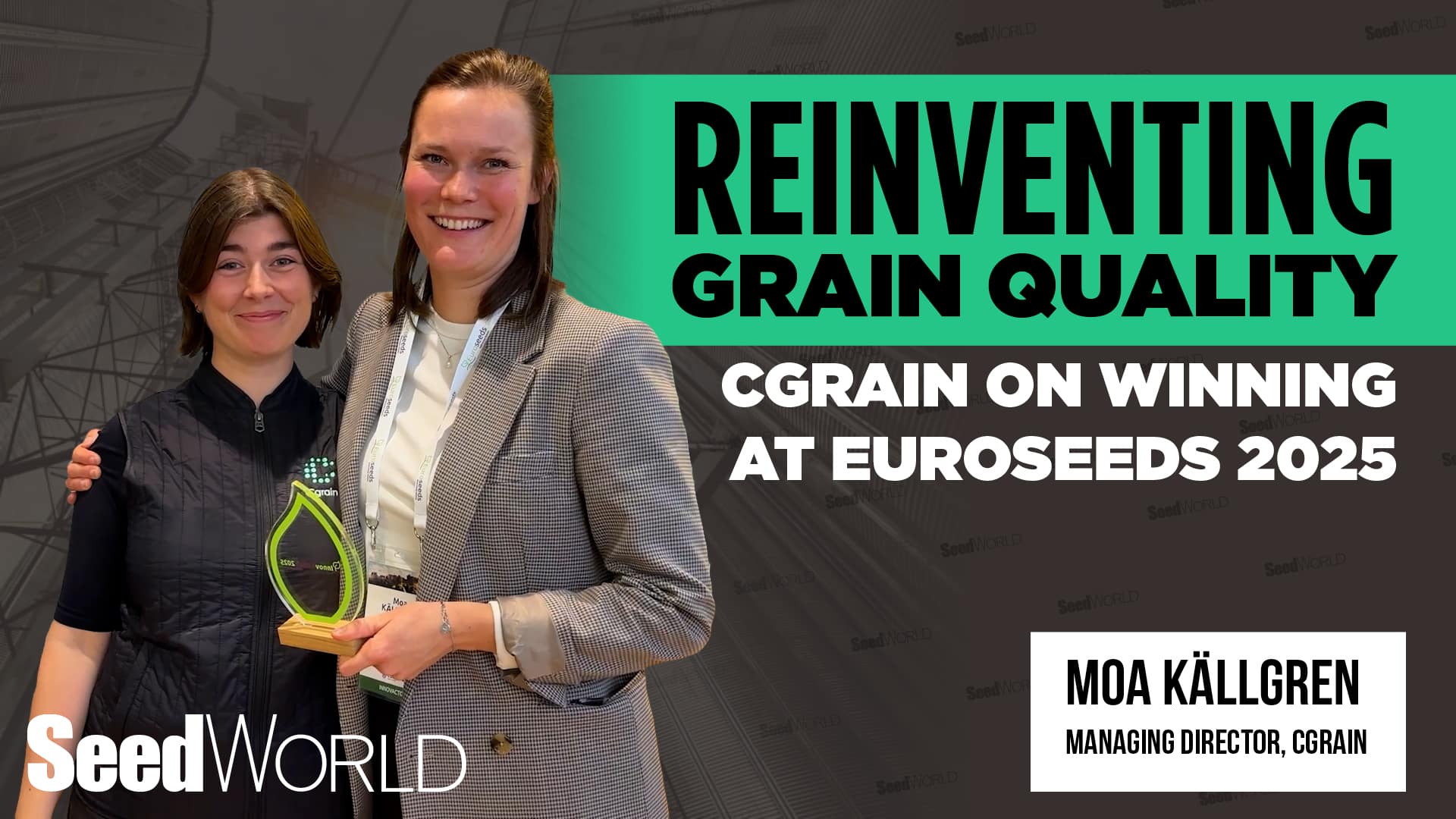

This week, Seed World Europe is featuring the third, second and first place winner of Euroseeds InnovAction Stage 2025. Today we are featuring third place winner Cgrain.

Grain grading has long been a monotonous, subjective, and time-consuming task. Skilled graders are increasingly scarce and costly, while global standards for grain yield and quality continue to rise. To address this challenge, Cgrain, together with Lantmännen, offer an AI-driven image analysis solution that automates ocular grain inspection. This innovation offers objective, reproducible, and scalable quality control to increase high-quality yield across the grain value chain. Anyone involved with manual ocular analysis knows that it comes with several issues. Here are three main issues and how Cgrain offers a solution for them.

Time and Monotony

Inspecting grain samples kernel-by-kernel, covering all surfaces of every grain, is not only repetitive but also highly time consuming and demanding.

Cgrain solves this with its patented V-shaped mirror design. As each kernel passes through the mirror, a built-in camera captures an image covering more than 90% of the grain’s surface — including the backside. This technology replicates the precision of detecting the same physical defects the human eye is capable of — without fatigue or subjectivity. In addition, the instrument analyses kernel size, thousand kernel weight, and sieving. The instrument automatically categorizes each kernel according to quality parameters, quantitatively and with images that can be accessed and saved. This solution eliminates monotony and frees up valuable time for graders to focus on other critical tasks.

Subjectivity and Inconsistency

Manual ocular analysis relies on human judgement, which introduces subjectivity and inconsistency. This makes achieving high accuracy and reproducibility challenging.

Cgrain solves this by using AI models trained on a rich database of grain images collected over several years across global regions, in collaboration with expert graders, grain authorities, and researchers worldwide.

Not only does this provide us with a rich and robust database, but we can also offer the flexibility to adapt our analysis models according to the costumer’s specific defect definitions and demands. The analysis performs consistently across all Cgrain instruments placed at different stages of the grain value chain, up until refinement.

The results? Objective grading with high reproducibility, no matter how many samples go through the instrument or the number of times the same sample is analyzed.

Overview of Yield and Quality

The monotony, subjectivity, and inconsistency of ocular analysis are factors that directly impact grain and seed quality. Without reliable grading, it is difficult to know whether the grains moving forward are truly the best, and if valuable kernels are discarded unnecessarily.

The Cgrain Value Sorter changes this. Using its advanced sorting mechanism, each kernel is imaged and categorized, but also physically directed by the instrument to the accept or reject bucket below. This process gives complete transparency as you can see the image of every kernel and whether it was accepted or rejected. This allows you to make more informed decisions, get a better overview, and increase your high-quality yield — because only the best grains move forward.

“We feel incredibly honoured and grateful for being named the 3rd runner-up at the 2025 Euroseeds InnovAction Awards in Edinburgh. It is truly a significant and meaningful achievement for us at Cgrain. Being a start-up, having the financial means and network to expand is always a challenge, making this recognition very meaningful to us. This award has provided us with a platform through which we are excited to develop new partnerships, collaborations, and adapt our innovation to the demands of the global grain industry. Most of all, we are eager to show a wider part of the grain industry who we are, what we do, and what value Cgrain can offer,” says Moa Källgren, managing director of Cgrain.

“Our ambition is to become the number one choice for automated ocular grain analysis tools. We want to contribute to better and improved quality analysis in the global grain value chain. We continue to develop analysis for small grains like wheat, and other cereals to meet the demands of the market. We also continue our work on certification and approvals of our analysis method. With our objective, accurate, and reproducible analyses, we can offer a higher degree of fair trading from farmer to industry while minimizing waste along the grain value chain.”

For more information, please visit www.Cgrain.ai or follow up on LinkedIn.