We find out from three experts about how canola and camelina could usher in a new era of renewable fuels as Canada’s Clean Fuel Regulations come into effect.

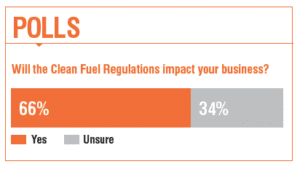

Earlier this year, the United States Environmental Protection Agency began looking at approving canola as a feedstock for renewable diesel, jet fuel and other fuels under the U.S. Renewable Fuel Standard. The Canola Council of Canada has hailed canola as Canada’s ideal resource for clean renewable fuels. Canada has implemented its own Clean Fuel Regulations, which in a nutshell will ensure the gasoline and diesel that Canadians use every day will become progressively cleaner over time, and affordable alternatives will be increasingly available to consumers. We consulted three experts to enlighten our webinar audience on Canada’s Clean Fuel Regulations, what they are, and what they could mean for the oilseed sector and specifically the seed industry as well.

The Clean Fuel Regulations are Canada’s new regulatory framework that require liquid fossil fuel primary suppliers to gradually reduce the carbon intensity of the gasoline and diesel that they produce and sell for use in Canada. It is supplanting and replacing our Canadian renewable fuel standard which sets a two per cent volumetric mandate for diesel fuel. Two per cent has to be of a bio blend. That’s been in operation since 2010. As of summer 2023, the Clean Fuel Regulations come into effect, and producers and importers need to satisfy this regulation. The goal is to achieve 30 metric tonnes of annual reductions in greenhouse gas emissions by 2030, contributing to Canada’s effort to achieve its overall greenhouse gas mitigation target of 15 per cent emission reduction below 2016 levels by 2030.

Does the canola sector have a history in the biofuels space?

The Canadian canola industry has over 25 years of proactivity in the biodiesel space. It has been a strategic priority as we seek policies that will have the positive net effects of:

- Being a source of sustainable domestic demand for farmers

- Providing market diversification opportunities for processed product

- Directly contributing to environmental policy goals of governments (decarbonization)

- Investing in rural communities through the expansion of value-added activities

How does this all benefit the seed space?

We see canola-based biofuels as a benefit to the economy and the whole value chain from the seed developer, to the exporters of a product and then the end users. So that’s the kind of overarching impetus as to why we are working in the biofuel space as an industry, and why farmers in the industry are interested in these types of policies. At a high level, the regulations provide options that allow Canadian-grown crops to be fully accepted as sustainable and compliant with land use and biodiversity criteria. It also recognizes regenerative farm practices such as no-till and minimal till, contributing to canola’s low carbon intensity and feedstock of choice in biofuel production. There are still several administrative issues to be finalized prior to summer 2023.

How do growers stand to gain?

The major benefit will be the development of a sustained, long-term new source of domestic market demand for canola. Canola farmers, the processing sector and biofuel producers now have a starting point to begin capturing market share.

Why is COPA so interested in this area?

Biofuels are a proven and viable solution to decarbonize transportation fuels in the here and now, as Steve said. When we talk about biofuels derived from crops like canola, they have a lower carbon footprint than conventional diesel fuel. When you talk about canola specifically, it has a lower carbon footprint of up to 90 per cent compared to conventional diesel fuel. Some of the biofuels that people are familiar with include ethanol and biodiesel. Biodiesel, of course, can be made from canola.

How will the Clean Fuel Regulations bolster the oilseeds sector?

In order to get biofuels uptake, and to have a market for biofuels, we need policy and regulations like this. We see demand for biodiesel and renewable diesel between Canada and the U.S. at roughly 11 billion litres today. Fast forward to 2030, we see the potential for that to grow to just over 17 billion litres. By 2025, we could see renewable diesel production capacity be close to 18 billion litres in the United States.

Not to be outdone, Canada has started to see opportunities arise. Right now we have close to zero production capacity for renewable diesel in Canada. In five years that capacity could explode to about four billion litres in this country, which is being led by some of the big energy players like Imperial, Tidewater and Parkland. They are starting to make big announcements, big investments in renewable diesel, not only because they’re required to under the Clean Fuel Regulations, but they also see it’s one of the best ways to decarbonize fossil fuels.

What does this mean for crush expansion?

Major announcements have been made in Canada by Richardson, Viterra, Cargill, and Federated Co-op/AGT with regards to canola processing. If all of those processing plants come to fruition as announced, that could grow crush capacity by close to six million metric tonnes by around 2027. And that would make the entire industry’s crush capacity grow by about 50 per cent. We’ve never before seen that type of expansion taking place here in Canada.

What could this mean in terms of use of canola in biofuels?

We see the potential for canola use in biofuels to grow from about two million metric tonnes (seed equivalent) in 2020, to about six and a half million metric tonnes by 2030. We see production continuing to increase, farmers continuing to be able to get better yields on their land. We have a high level of optimism that we’ll continue to see productivity gains for canola, reaching production volumes of about 29 million metric tonnes by 2030. Of course, when you take 6.5 million tonnes used for biofuels by 2030, and about 29 or 30 million metric tonnes of production between Canada and the U.S. by 2030, that’s still about only a quarter of our canola being used towards biofuels. The rest of our canola will continue to be used for traditional purposes, as a food and feed ingredient.

Could we see new varieties bred specifically for biofuel use?

We’re just starting to ask some of those questions and have those conversations in terms of what’s feasible as it relates to higher oil content. There’s a trade-off. If you’re going to have higher oil content, what does that mean in terms of protein content? We want to make sure we have maximum value there. We also don’t want to compromise yield. Bushels per acre is important. We need to check all the boxes in terms of maintaining protein, maintaining and increasing yield, and also driving higher oil content if possible. It could also pave the way for other oilseeds like camelina, carinata and pennycress.

Chris mentioned camelina, which your company specializes in. What is so special about this oilseed?

We’ve been breeding this very interesting crop for almost 20 years, but it’s a crop that’s been around for thousands of years. If you take a look at the historical record back as far as Neanderthal man, Vikings, Egyptians and the ancient Romans, the point of origin of this crop is in the eastern Mediterranean, and actually all the way up to Siberia ‚Äî it’s one of the very few broadleaf annual winter crops that survives the winter. We like the crop because it’s very well suited to dryland production in Western Canada. It’s frost tolerant in the early stages and drought tolerant later, and it’s a lower-input crop.

Why could it make good biofuel?

From a carbon intensity point of view, it ticks a lot of boxes that people are looking for in biofuel feedstocks. When we started breeding this crop, it didn’t have a lot of the agronomics that you’d want an oilseed to have to be competitive. Small seeded, no disease resistance, no herbicide resistance. With our conventional breeding program over the years, we were able to increase the seed size by over 40 per cent without a yield drag, which is significant because if you know anything about oilseed breeding in general, typically seed size is negatively correlated to oilseed yield.

We were also able to develop a variety that has quantitative resistance to downy mildew, which is one of the few things that bothers this crop. It’s taken us a decade and we just released a real game changer for the crop, which is a broadleaf Group 2 herbicide tolerance. We feel the crop is now really able to take its place among oilseed rotations.

What kind of growing zones are we talking about?

Typically, our sweet spot for production is the drier, lighter soils where canola typically will yield 25 to 30 bushels an acre, and we’re very competitive in that regard. Camelina will yield the same, but our seed costs are significantly lower and our input costs lower, so it’s more favourable to the grower’s bottom line in areas where they wouldn’t normally get their 50 bushel an acre canola, and they could defray the cost of all those expensive inputs and expensive seed costs.

You mentioned camelina having some genetic ties to Siberia. Why is that important here?

Over the millennia, certain landraces of this oilseed have developed to require true vernalization. They need to be frozen in the fall and thawed out in the spring to grow. It’s the only oilseed that we know of that can actually survive consistently over the winter in the northern tier states and Western Canada. We plant in the fall, it gets to a small stage, it freezes. As soon as the spring comes, it starts to grow again.

What’s the outlook for this crop in terms of biofuel feedstock?

If you take a look at all the big players that have been building these huge processing facilities that Chris touched on, where is the feedstock going to come from? I’m a big believer in following trends. Renewable Energy Corp. was purchased by Chevron a few months ago. Now, Chevron has announced huge increases in renewable biofuels. They need feedstock. Camelina is a great fit. It’s part of the solution; not the entire solution itself, because the scale of the total feedstock requirement is so overwhelming. We’re the leader in camelina development. We’ve been doing it for 20 years. It’s a super exciting time for our company.