In the world of seed processing, where precision and efficiency are paramount, the choice of equipment and its seamless integration can significantly impact the success of a project. While diversity in equipment options may seem appealing, a growing trend suggests that opting for a more unified approach can simplify the entire process, from planning to execution.

The Power of Compatibility: One of the key considerations in seed processing projects is the compatibility of various equipment components. The assertion that certain combinations of equipment, whether from the same manufacturer or different ones, have proven to work together seamlessly is crucial. This compatibility reduces the risk of integration failures, streamlining the entire project.

Simplified Planning and Coordination: Early-stage planning is the foundation of any successful seed processing project. Simplifying the purchasing and planning process becomes more feasible when there are fewer entities to coordinate with. Whether it’s an individual managing the project or a third-party professional overseeing the work, having a single supplier for most details can significantly enhance the efficiency of planning and coordination.

Reducing Accountability Ambiguity: A notable advantage of choosing a single supplier for seed processing equipment lies in the reduced risk of accountability ambiguity. When multiple suppliers are involved, potential disagreements may arise regarding responsibility for integration issues or oversights in the planning and construction phases. A single source for information reduces such risks, fostering a clearer line of accountability.

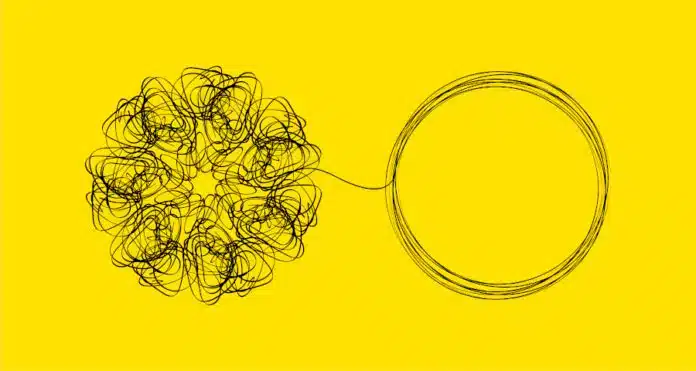

The Crucial Role of Integration: Within seed processing projects, the integration of various components is where the bulk of the work lies. From the building’s dimensions to the connections between major equipment and the intricate conveyors that facilitate movement, meticulous planning is necessary. The interfaces between machines and conveyors often require detailed attention, and differences between manufacturers can complicate the integration process.

Logistical Ease and Efficiency: In the seed processing world, opting for a streamlined approach not only eases the logistical burden but also enhances efficiency. Gathering details from a single source simplifies the electrician’s and millwrights’ tasks, reducing the chances of oversights or conflicting information. A well-coordinated project with fewer entities involved is more likely to lead to a smoother build and startup process.

While I advocate for a more unified approach, I don’t want to discourage diversity in equipment choices. Every piece of equipment doesn’t have to be from the same manufacturer. That said, simplicity and coordination in seed processing make everyone’s job easier. Working with a knowledgeable provider is the first step to begin simplifying your processing line and making life easier for yourself and your employees.