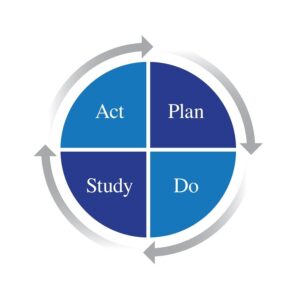

Lean Manufacturing at our company is plugged to the continuous improvement of our operations. When we started with this concept, we decided to begin our project by working on one treating and bagging facility. We did this because we wanted to start at a small scale and check if lean suits Euralis or if Euralis suits lean! Our first project was to set up a system for Visual Management of Performance and work on the basics of continuous improvement. We created 5-minute daily meetings. Led by a workshop leader, the 5-minute meetings aim to analyse the production of the day before in terms of Safety, Quality and Productivity, and secondly, it’s the meeting where everyone can propose improvements. Here starts rolling the famous Deming or PDCA Wheel (‘plan, do, check, adjust’). After that we were able to proceed towards a more incentivizing project. When deploying the project on our various sites, there are five main ‘axes’ that we focus on: Master your territory; Give meaning to your actions; Enliven and lead your team; Delegation of simple problem solving; and Pilot the progress plan.

In all our efforts, we now realize that the main topic revolves around industrial culture, and how to bring people to change their way of working! The project is going very well, and I am happy to say that thanks to its great success, this project will now be extended in all factories of Euralis Seeds: Sevilla in Spain, Cherkasy in Ukraine, and Lescar in France.