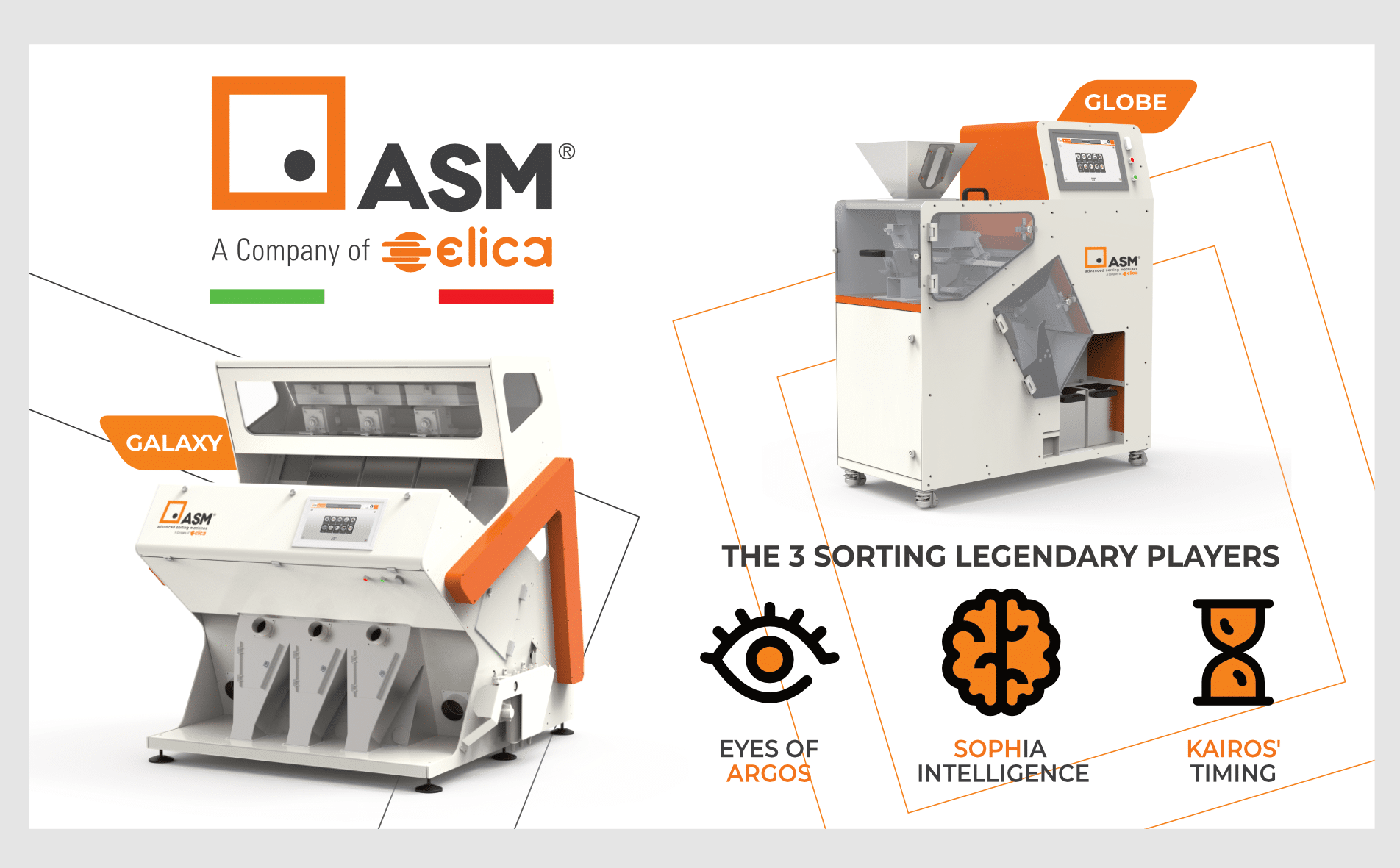

With the launch of Galaxy and Globe, Elica ASM broadens technological horizons, introducing two new optical sorters conceived to address distinct yet complementary industrial requirements. Both models combine a compact, refined design with an advanced control architecture, ensuring seamless synergy between optical systems, electronic management, and proprietary AI-driven processing.

At the core of both sorters leads the ARGOS vision system, based on ultra-high-resolution 4K UHD quad-linear cameras capable of operating in multispectral mode through RGB, NIR (Near Infrared) and SWIR (Short-Wave Infrared) channels, enabling the analysis of materials with unique reflectance or properties.

This architecture enables simultaneous, real-time detection of color, shape, and structural defects, ensuring comprehensive inspection of granular, semi-processed, or morphologically sensitive materials. The new Optical Sensor System performs micrometric-level scanning, for high precision and accuracy.

A key functional advantage for cereals, vegetable seeds, and forage sectors is the ability to identify and remove a wide spectrum of contaminants. The system supports the removal of off-type seeds, foreign varieties, and contaminating botanical species, ensuring stronger varietal purity across seed lots. It also detects and rejects seeds with poor germination potential, allowing processors to obtain batches with higher germination rates. Additional functions include the elimination of damaged or physiologically compromised seeds, as well as foreign bodies such as sticks, stones, soil particles and inert contaminants frequently present in raw agricultural streams.

The illumination system, entirely designed by Elica ASM, maximizes detection efficiency. Based on high-intensity and multi-frequency LED modules, it provides focused and adjustable lighting in terms of angle, spectrum, and intensity to adapt to different product types and operational conditions.

This configuration eliminates shadows and parasitic reflections, ensuring consistent light distribution over the entire inspection surface. Light beams are calibrated according to the optical properties of the material, enabling a clear distinction between defective and conforming product.

The entire process is managed by SophIA, a proprietary software platform built on artificial intelligence algorithms. It processes raw data from the optical sensors in real time, dynamically classifying products and automatically adapting to variations in shape, color, structure, or contamination.

Each anomaly is identified, compared with internal datasets, and processed through machine learning algorithms, allowing not only complex selections but also the creation of self-optimizing selection programs based on desired performance targets. The system supports remote access, real-time reporting, and compliance with Industry 4.0 and 5.0 certification standards, ensuring full data traceability and integration with digital manufacturing environments.

The KAIROS ejection system is engineered with high-efficiency ejector valves, whose pitch — 2.0, 2.5, 3.3, 4.5 mm — is defined according to the machine type. This technical configuration enhances ejection accuracy, enabling selective defect removal and maintaining maximum sorting efficiency across different processing capacities.

The valves are electronically activated with microsecond-level response times, perfectly synchronized with product flow through a predictive control logic. This configuration allows for the removal of individual defective particles without affecting overall production throughput. It minimizes false rejects of conforming material and improves the overall yield of the installation, maintaining final product purity within certified tolerances.

Globe is designed for medium-capacity plants, laboratory installations, or production lines handling delicate or irregularly sized materials. Its compact structure with different types of chute makes it ideal for precise treatments, even with light, fragile, or easily breakable products.

Galaxy, on the other hand, is built for high-volume processing and dense material flows. Its multi-chute configuration (up to 7 channels) enables parallel sorting of large product quantities, ensuring operational continuity and scalability. It is ideal for industrial facilities that require consistent performance, rapid recipe changes, and minimal downtime.

Both models are entirely designed and assembled in Italy according to strict European industrial standards and certifications. The supporting frame is made of painted steel with easily accessible panels, certified components, and low-impact materials. The modular design ensures simplified maintenance, optimal accessibility to all main subsystems, and efficient cleaning even in demanding environments.

The use of low-energy components and partially recyclable materials strengthens Elica ASM’s commitment to sustainable production without compromising robustness or durability.

Each sorter is built with an IP6X protection rating, ensuring complete dust sealing and reliable performance even in harsh environments. All materials in contact with the product comply with Food Contact regulations, while specific configurations are available in ATEX-certified versions for operation in explosive or dust-sensitive areas.

The integrated remote diagnostics system and software update management reduce maintenance costs and ensure maximum operational continuity, even across geographically distributed facilities. The structured post-sales service provides customers with continuous training, periodic updates, and constant technical support.

Galaxy and Globe are not merely optical sorters — they represent a technological leap in automated quality control. Designed to anticipate the future of production, they integrate high-definition vision, supervised machine learning, and high-efficiency ejection systems, offering customizable, Industry 5.0-ready solutions for every production line and guaranteeing superior purity by effectively removing non-germinating seeds, damaged material, foreign varieties, and external contaminants.