Iowa State researchers say this agricultural byproduct could be the game-changer in reducing nitrates, at a fraction of the cost.

Corn cobs might outperform woodchips in reducing nitrates in water-quality bioreactors, offering a more cost-effective solution, according to researchers at Iowa State University. The challenge lies in securing a sufficient supply of corn cobs.

Bioreactors, used to treat nitrate-nitrogen in tile drainage from crop fields, are below-ground troughs where tile water interacts with a high-carbon material like woodchips in a low-oxygen environment. This process nourishes microbes that transform the nitrate primarily into harmless nitrogen gas before the water exits into waterways or ditches.

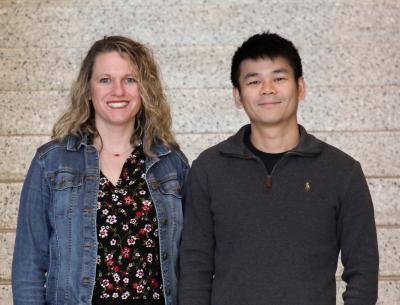

Michelle Soupir, a professor in agricultural and biosystems engineering at ISU, has been a leader in developing bioreactor technology. Woodchip bioreactors, with an estimated lifespan of about a decade, provide average nitrate reductions of 15-60% at costs of $10,000 to $15,000 (around $10.23 per treated acre).

In 2018, Soupir began exploring corn cobs as an alternative carbon source for bioreactors, based on lab studies showing their increased biological activity and nitrogen removal potential compared to woodchips. The research team set up an experiment at Iowa State’s pilot-scale mini-bioreactor research site to evaluate nitrate removal rates, efficiencies, and costs of different woodchip-corn cob mixtures.

“We had lab studies that showed corn cobs are more biologically active and could increase nitrogen removal over woodchips,” she said in an ISU news release. “We wanted to test this at a larger scale to answer a number of questions, including how long corn cobs would last compared to woodchips, their hydraulic properties and their costs.”

After four years, they found that bioreactors with corn cobs had higher nitrate removal rates than those with 100% woodchips, with the 75% corn cob mix performing best. The corn cob bioreactors also had similar hydraulic properties to woodchips, with the 75% corn cob systems having the best hydraulic efficiencies. The costs per amount of nitrogen removed were 22-60% lower in the 75% corn cob bioreactors than in those with 100% woodchips.

“It was great to see that the systems with higher levels of corn cobs showed such positive results for these parameters,” Soupir said. “Also, we were surprised to find that the corn cobs, which tend to be larger than the woodchips, clumped less and degraded more slowly than the woodchips. This suggests they are likely to have a longer life span than we originally estimated, which would further reduce costs and maintenance requirements.”

The researchers noted that corn cobs clumped less and degraded more slowly than woodchips, suggesting a longer lifespan and further cost reductions. However, a field-scale bioreactor requires about 60 – 180 cubic yards of material, which can be challenging to source due to existing markets for corn cobs in bioproducts.

“That’s a lot,” said research partner Ji Yeow Law, an agricultural and biosystems engineering research engineer who conducted the economic evaluation for the project. “We think of them spread across Iowa fields, but it is actually tough to find them available in the amounts needed. There is already a pretty good market for them for bioproducts and other purposes. But we are looking into possible sources, such as seed corn companies.”

The research team, in addition to Soupir and Law, includes Tom Isenhart, professor of natural resource ecology and management; Morgan Davis, former graduate student now an assistant professor at the University of Missouri’s School of Natural Resources; and USDA ARS scientists Tom Moorman (retired) and Gary Feyereisen.

This year, the team plans to study a bioreactor using 100% corn cobs as a carbon source, funded by a Conservation Innovation Grant from the Natural Resources Conservation Service. Although the project’s funding for corn cob treatments extends only for one more year, Soupir expressed hope for continued research on their effectiveness.

The team is also exploring other carbon sources, including various types of woodchips, and methods to enhance bioreactors’ efficiency, such as increasing water flow from fields to boost nitrate removal.

Interest in bioreactors as an effective edge-of-field practice grew after the Iowa Nutrient Reduction Strategy’s 2012 science assessment indicated the state’s need for 76,000 to 133,000 bioreactors, along with other practices, to achieve its strategy goals. Over a decade later, while the state is still far from reaching those numbers, there is growing momentum for bioreactor installation.

“Bioreactors can be an important tool to improve water quality in our agricultural state,” Soupir said. “This research represents continuing work to make the next generation of the technology even more effective, practical, and cost-effective.”

The research, supported by the Iowa Nutrient Research Center and summarized in the Journal of Environmental Management, continues to explore alternative carbon sources and ways to increase bioreactors’ effectiveness. With ongoing interest in bioreactors as a tool for improving water quality, this research aims to make the technology more effective, practical and cost-effective.