Universities and state legislatures across the country see the need for and potential of investing in plant science centers.

Interest is strong among universities to invest in plant science research. Across the country, institutions are announcing new collaborations and, in many cases, turning ground to construct multi-million dollar facilities that will expand existing programs or launch new ventures.

For many, it’s simply time to create modern facilities or realize the extra space they need because of robust programs. Other university leaders say they’re responding to calls within agriculture to deliver more highly-qualified students and more nutritious and resilient plants. Combine that with investments in the latest technology — everything from robots to gene-sequencing platforms — and these institutions believe they can accelerate the pace of research and development for the benefit of a hungry population and a more sustainable agriculture system.

Raven Precision Agriculture Center at South Dakota State University

South Dakota State University (SDSU) was the first institution in the nation to offer a four-year degree in precision agriculture and soon, they’ll have a new facility to complement their program, the Raven Precision Agriculture Center.

John Killefer, dean of the College of Agriculture, Food and Environmental Sciences at SDSU, says the $46.1-million building will be “the first and most advanced facility dedicated to precision agriculture education and research.”

A groundbreaking ceremony was held in early October 2018 for the 129,000-square-foot structure and work is expected to commence in the spring of 2019. Private donors and funding authorized by South Dakota’s state leaders help fund the project.

Killefer says precision agriculture is valued in places such as South Dakota with variable production environments, noting the region’s farmers were early adopters of this technology.

“Stakeholders were informing us of the need for graduates with expertise in agronomic practices, basic engineering and data sciences. We already have programs that provide that expertise so the new Raven Precision Agriculture Center will allow us to bring all those disciplines together.

“The center is designed to provide unique learning environments,” Killefer says. “The classrooms will allow precision ag equipment of all sizes to be present during lectures and labs, including full-size combines.

“The center will enable us to integrate faculty with different expertise under one roof. There will also be space for industry partners, so students will have opportunities to work on real-life challenges. The center was designed with synergy and collaboration in mind.”

Killefer says the Raven Precision Agriculture Center will focus its efforts on projects such as developing new data handling processes, testing new sensors and equipment that come on the market and studying new practices that most efficiently use on-farm resources while maintaining profitability.

“This center will help us prepare our students to help producers most fully utilize the technologies of today and tomorrow,” he says.

Using technology is becoming increasingly important as farmers seek to feed a growing population in a sustainable manner.

“Precision agriculture will have a tremendous impact on optimizing productivity and conserving natural resources,” Killefer says. “There are individual disciplines associated specifically with equipment, seed technology, soils, and data-analytics for example, and we will bring these all together in our teaching and research activities.

“We want to help our graduates to be the leaders and decision-makers of tomorrow that best utilize technology to address challenges and opportunities associated with equipment, data, seed technology, labor, policies and economics.”

Plant Sciences facility at Washington State University

In 2017, Washington State University approved the construction of a new plant sciences facility, and that project was formally started in June 2018 when local dignitaries donned hard hats and turned that ceremonial shovel of dirt at the site of the newest building in the V. Lane Rawlins Research and Education Complex on the Pullman campus. Their plans call for erecting a four-story, 95,000-square-foot building that will serve as a modern research venue for plant biochemistry, plant pathology, horticulture and crop and soil sciences. Those programs and facilities are currently housed in buildings that were constructed more than four decades ago.

John Peters, professor and director of the Institute of Biological Chemistry at Washington State University says several factors prompted university leaders to consider investing in a new facility.

“WSU is known for the strength of our plant sciences programs, but our facilities are aging,” Peters says. “Additionally, we recognize the importance of basic research in plant sciences to Washington’s agriculture sector.”

The $52-million project was authorized by the state legislature in 2018 and made possible with funding from the legislature, state agricultural commissions and the U.S. Department of Agriculture’s Research Service.

The new plant sciences facility will feature an open laboratory layout with dedicated spaces for imaging and microscopy, mass spectrometry, plant growth and phenomics. Its design will allow for collaboration between its many users.

“The building will house researchers in plant physiology of plant development, carbon allocation, photosynthesis, production of plant-based products, nitrogen fixation and plant resilience,” Peters says. “Our goal is to create state of the art facilities for basic plant science research that has the potential to impact Washington’s $51 million food and agriculture industry.”

Plant Growth Research Facility at the University of Missouri

The doors of the University of Missouri’s new Plant Growth Research Facility are on schedule to open in April 2019. Back in 2006, university leaders acknowledged the need to expand their plant biology facilities and placed the project on the campus master plan, says Robert Sharp, professor of plant sciences and director of the Interdisciplinary Plant Group.

“In fall 2016, the University of Missouri (MU) Board of Curators approved $28.2 million in funding for the current development, which represents the first phase of the East Campus Plant Growth Facility,” Sharp says.

“Providing plant growth facilities on the MU campus that match the caliber of the researchers within the plant biology community has been identified as an important need for more than a decade. Plant Biology is a major strength at the University of Missouri, with more than 100 faculty and their lab members from multiple departments and divisions in several colleges across campus.”

Construction began in the fall of 2017 on the building that will include approximately 23,000 square feet of greenhouse space, more than 9,000 square feet of space for controlled environment plant growth chambers and expanded long-term seed storage capacity. It will complement the existing Ernie and Lottie Sears Plant Growth Facility built in 2001 and named in honor of the husband and wife research team who “made significant contributions to the advancement of rust-resistant wheat varieties,” Sharp notes.

MU is confident that multiple goals can be achieved through this infrastructure investment.

“With the new facility, expanded research avenues can be explored while enhancing research funding and recruitment and retention of top-flight faculty and students, which will allow the campus to further enhance its national and international reputation in plant biology research and education,” he says.

Some of those expanded research opportunities will be made possible by unique features of the Plant Growth Research Facility, such as extended height growing chambers and the use of field or non-sterile soil.

Sharp says some greenhouse modules will allow for plant growth up to 21 feet and several growth chambers will accommodate plants up to 11.5 feet tall.

“This will allow studies all the way from Arabidopsis, a model genetic organism for plant biology research for which studies began at MU that is now used worldwide, to tall plants like maize as well as bioenergy grasses like switchgrass and sorghum, and also tree species. This allows us to work with plants that we haven’t been able to work with in the past. Even corn, in our existing facilities, can be pushing up into the lights by the time it reaches reproductive development,” he says.

Extra growth height will help researchers, particularly root biologists, better replicate field conditions in a controlled environment. For example, in the case of corn, which sends out roots six feet or more into the soil, abnormal root systems develop when it’s grown in pots, he noted.

In their existing Sears Plant Growth Facility, MU only uses sterilized soil mixes to ensure no pests or diseases would be introduced into the building, but that has limited certain types of research.

“The new facility has been designed with one range of greenhouses separate from the others to allow scientists to work with field soil yet still avoid problems of contamination,” Sharp says.

The university is confident that the work to be accomplished in the Plant Growth Research Facility will have far-reaching impacts on the seed industry and beyond.

“Several MU plant scientists study the regulation of seed metabolism, including oils, amino acids and macro and micro nutrients, with a goal of developing crops with improved nutritional qualities for animal and human health. The interaction of plant biology and human health is an area of expanding focus,” Sharp says.

He notes that professor Ron Mittler, a recent joint hire between the Division of Plant Sciences and School of Medicine, is examining signaling pathways that are involved both in plant stress and cancer biology.

Center for Agricultural Synthetic Biology at the University of Tennessee

The University of Tennessee Institute of Agriculture formed the Center for Agricultural Synthetic Biology (CASB) in September 2018. It’s believed to be the world’s first synthetic biology center aimed specifically at improving agriculture.

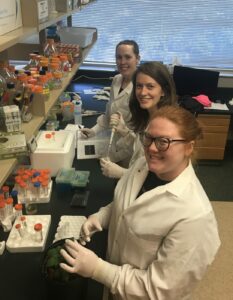

According to the university, the CASB “will perform mechanical tasks for research teams such as automated production of single cells from crop plants and cultures, gene editing, rapid design-build-test cycles and direct writing of DNA into single cells ‚Ķ the CASB is capable of engineering and analysis of biological materials in a contained platform.”

The center is already using a plant genome editing robot that screens and transforms plant cells with synthetic DNA.

Their goal is to design plants with improved traits including drought-resistant grasses and fresh produce that can retain their healthful qualities during long storage periods.

In October, the CASB was awarded $7.5 million from the U.S. Defense Advanced Research Projects Agency (DARPA) to create sentinel potato plants that can detect environmental threats. These modified specimens would be used to protect deployed troops and civilians who may encounter substances such as nerve agents and radiation.

Neal Stewart, a professor of plant sciences at the UT Herbert College of Agriculture, and Scott Lenaghan, an assistant professor in the Department of Food Science who also holds an adjunct position in the Mechanical, Aerospace, and Biomedical Engineering Department, serve as co-directors of the CASB.

The creation of the CASB was a joint effort of the Departments of Plant Sciences and Food Science and received funding assistance from the University of Tennessee AgResearch.

Texas Genomics Core Alliance

In October 2018, Texas A&M University and the University of Texas at Arlington formed the Texas Genomics Core Alliance. According to David Threadgill, PhD, director of the Texas A&M Institute for Genome Sciences and Society, the newly announced alliance was made for many practical purposes.

“With the growing cost of research and the increasing importance of sequencing technologies, we are always exploring ways to reduce costs,” he says. “Sequencing is an area where cost is driven by technology and usage.

“Newer technologies are cheaper and higher usage increases purchasing power and garners greatly reduced costs. It was a logical step to combine user bases to increase the usage and purchasing power that can then be passed down to individual users.”

The creation of the Texas Genomics Core Alliance won’t include any facility changes or additions but will allow researchers greater access to technologies from both institutions, Threadgill says, particularly automation and single-cell genomics and bioinformatics. Texas A&M’s Molecular Genomics Core in the Institute for Genomics Sciences and Society is home to several automated sequencing platforms that prepare and analyze samples. The University of Texas at Arlington’s contribution to the Alliance are powerful, high-throughput sequencing systems, currently in use at the North Texas Genome Center.

It’s not the first time state-based institutions have banded together to combine their operations — Threadgill points to the New York Genome Center — but the alliance in Texas stands out because of its more diverse user base.

“What makes us unique is the others have usually been based on sequencing for clinical applications. Our primary users are much broader coming from fields like veterinary medicine, ecology, agriculture, evolution and also medicine that often require unique sample preparations and bioinformatic analysis,” he says.

All of those users, including plant scientists, will benefit from the accelerated pace of research and development that will be made possible by reduced costs and shorter turn-around times for generating data, he says.

Controlled Environment Phenotyping Facility at Purdue University

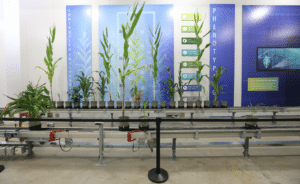

In April 2018, Purdue University’s Institute for Plant Sciences opened the doors to their new Controlled Environment Phenotyping Facility. The building project was designed to allow for more capacity and better data quality that comes from “highly consistent and uniform environmental conditions” as scientists look to better understand that impact of specific genomes, says Yang Yang, the director of digital phenomics at Purdue University.

The new facility, at about 7,300 square feet, includes one large climate chamber equipped with conveyors and robots to move and care for fully-grown plants such as hybrid corn and sorghum plants, along with automated RGB and hyperspectral imaging systems that can accommodate plants more than 15 feet tall. The controlled environment setting also features precision irrigation technology that can administer weight-based irrigation management.

“The goals of the facility are to position Purdue as a leader in plant phenotyping using state-of-the-art imaging and sensing technologies; to facilitate and strengthen plant research programs at Purdue University and our ability to deploy discoveries for global impact,” Yang says.

In addition to the large growth chamber and fertigation and imaging technologies, the Controlled Environment Phenotyping Facility (CEPF) is unique in the integrated data pipeline system it uses for image analysis, data mining and delivery, Yang adds.

“The technologies deployed in Purdue’s CEPF can empower researchers to acquire a much better understanding on the connection between a crop’s genomic background and its phenotypic performance at much more efficient and consistent manners, thereby accelerating the efforts in breeding for newer varieties with higher yield and better stress tolerance traits,” Yang says.

“In and by itself, Purdue’s CEPF is the combination of expertise of multiple disciplines, such as biology, engineering and data sciences, which make the CEPF a perfect ‚Äòmelting pot’ for students of different disciplines to acquire the interdisciplinary experiences and education that one would otherwise be hard-pressed to achieve without a facility as the CEPF.”